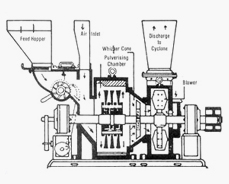

| We are proud to state that we are one of the few exceptions in this growth oriented industry to offer high class Impact Pulverizer. Impact Pulveriser Technical Details Swing hammer type grinding chamber lined with replaceable lining plates, built-in whizzer classifier strong suction blower. All the wearing parts of the grinding chamber ,whizzer. Classifier and the blower are lined with replaceable lining plates. The main driving shaft (EN-8) runs on a pair of heavy duty self aligning Ball/Roller Bearing fitted in dust proof bearing housing. The hammers are forged steel coated with very hard alloy. Cyclone Air Separator complete with connecting pipes and angle iron frame for cyclone. A Automatic feeder is provided for regular feed and static type dust collector with angle iron frame. used in a various applications like: Turmeric, Stones, Bauxite, Bentonite, China Clay, Coal, Gypsum, Soapstone, Graphite & Tamrind Seeds etc. Impact Pulverizer

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||